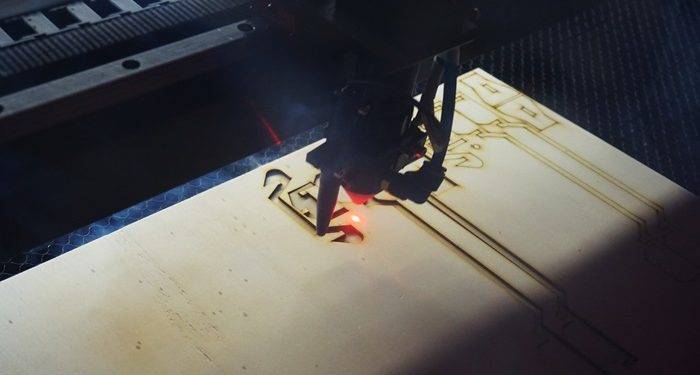

If you’re familiar with laser cutters, you may already know about their amazing ability to precisely cut through materials like wood, plastic, and metal. But did you know that there are many other unique uses for this versatile machine? In this article, we’ll take a deeper look into the world of laser cutting and explore eight surprising ways it can be utilized, so get ready to unleash your creativity!

Customized Gifts and Decorations

With a laser cutter, you can easily create personalized gifts or decorations for special occasions like birthdays, weddings, or holidays. From custom engraved wine glasses to intricately cut wooden signs, the possibilities are endless. This makes it a great tool for DIY enthusiasts or small business owners looking to add a personalized touch to their products.

Prototyping and Product Design

When it comes to product design, precision is key. With a laser cutter, you can quickly and accurately create prototypes of your designs, saving time and money in the process. This makes it an essential tool for engineers, architects, and designers who need precise measurements for their projects.

Some potential prototype ideas that can be explored with a laser cutter include electronic enclosures, architectural models, and even fashion designs. With its ability to cut through various materials and create intricate designs, the possibilities for prototyping are endless. The accuracy of laser cutting also allows for fine-tuning of designs before moving on to production, ensuring a high-quality end product.

Model Making

Whether you’re building models for tabletop gaming or creating architectural models, a laser cutter can help bring your designs to life with incredible detail. By using various thicknesses of materials and adjusting the laser’s power, you can achieve different levels of depth and texture in your models.

Artistic Creations

Laser cutting has opened up a whole new world of possibilities for artists. From intricate paper cutouts to stunning etched designs on glass, the precision and speed of a laser cutter allow artists to push the boundaries of their creativity. It’s also a great way to reproduce your artwork in different mediums, such as wood or metal.

When working with a laser cutter, it’s essential to prepare your materials properly to ensure the best results. For wood, you’ll need to sand down any rough edges and remove any splinters before cutting. For acrylic or plastic, using masking tape can help prevent unwanted burn marks on the surface of the material. Metal surfaces may need to be cleaned and polished before cutting to ensure a smooth finish. Don’t forget to adjust the power and speed settings of the laser cutter based on the thickness and type of material being used for optimum results. With proper preparation, you can achieve clean and precise cuts without damaging your materials.

Signage and Branding

For businesses, having a unique brand image is crucial. With a laser cutter, you can create eye-catching signage and branding materials that will make your business stand out. Whether you’re engraving logos onto wooden signs or cutting out vinyl decals for windows, a laser cutter offers endless possibilities for creating professional and eye-catching branding materials.

Jewelry Making

Gone are the days of using traditional hand tools for jewelry making. With a laser cutter, you can easily cut intricate designs on different types of metal, allowing you to create unique and detailed pieces of jewelry. You can also use the laser to engrave personalized messages or designs onto pendants and charms.

Jewelry making can be a time-consuming and delicate process, but with a laser cutter, it becomes faster, easier, and more precise. By using a laser to cut through metal instead of traditional hand tools, jewelers can achieve intricate designs in a fraction of the time. The precision of a laser cutter also allows for consistent cuts every time, ensuring that each piece of jewelry is symmetrical and flawless. This makes it an essential tool for both amateur hobbyists and professional jewelers alike.

Textile Design

Laser cutting has revolutionized the world of textile design by allowing designers to quickly and accurately cut through fabrics without fraying or tearing them. This opens up endless possibilities for creating intricate patterns, shapes, and designs on various fabrics, from leather to silk.

Before using a laser cutter to cut fabrics, it’s important to prepare them properly. This involves ensuring that the fabric is flat and taut, as any wrinkles or loose areas can cause issues during the cutting process. You should also test your chosen fabric with the laser cutter before starting on your final design to ensure that it cuts cleanly and accurately. Be sure to use minimal adhesive when securing the fabric onto the cutting bed, as too much glue can cause discoloration or burning of the fabric.

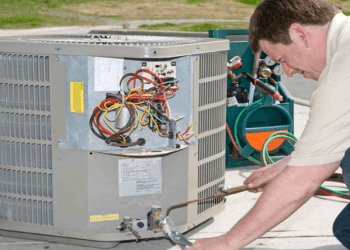

Maritime and Construction Applications

In addition to its creative uses, laser cutters also have practical applications in maritime and construction industries. Shipbuilders use laser cutting to create precise holes and cuts in metal plates for shipbuilding, while architects can use lasers to quickly cut through materials during the construction process. The precision and speed of a laser cutter, with tools and help from West Australian Steel Sales, make it an invaluable tool for these industries.

So there you have it—eight unique uses for a laser cutter that go beyond just cutting through materials. With its precise measurements and versatile capabilities, this machine is an essential tool in various industries and hobbies. Why not try exploring some of these uses yourself? Who knows where your creativity will take you!