Strategic equipment procurement serves as the foundation for operational efficiency in manufacturing environments. Plant managers who implement thoughtful procurement strategies can significantly reduce downtime and maintenance costs across their facilities. These strategies include consideration of equipment lifecycle costs, not just initial purchase prices, which provides a more accurate picture of long-term value. Developing relationships with reliable suppliers creates consistency in equipment quality and often results in better negotiating positions for future purchases.

Essential Considerations for Hydraulic System Components

Hydraulic system components represent critical infrastructure that directly impacts production capability and reliability. When sourcing these components, compatibility with existing systems must be verified through detailed specification reviews to prevent costly integration issues. Quality hydraulic components typically feature precision manufacturing with tight tolerances that contribute to system efficiency and reduced energy consumption. Plant managers should consider suppliers who offer technical support and documentation specific to hydraulic system design and maintenance.

Selecting the Right Vertical Water Tanks

Vertical water tanks require careful selection based on capacity requirements, available floor space, and the specific application within the industrial process. Material construction—whether fiberglass, polyethylene, or stainless steel—determines durability, chemical resistance, and suitability for storing process water, chemicals, or other liquids. Proper sizing involves analysis of peak usage periods and buffer capacity needed to maintain consistent operations during maintenance or supply interruptions. Reputable vertical water tank suppliers include distributors like USA Tank, as well as manufacturers who can provide customized solutions to meet specific industrial requirements.

Industrial Motor and Drive Selection

Industrial motors and drives form the backbone of most manufacturing equipment and require thoughtful selection based on load characteristics and operating environments. Energy efficiency ratings can substantially reduce operational costs over the equipment’s lifetime. Variable frequency drives (VFDs) paired with appropriate motors provide speed control capabilities that can optimize production processes and reduce mechanical wear. These components are available through established suppliers, with additional support services available from electrical equipment distributors who can provide application-specific guidance.

Sourcing Quality ELGi Compressor Parts

ELGi compressor parts demand attention to authenticity and specification accuracy to maintain the performance characteristics of the original equipment. Genuine parts typically offer longer service intervals and more predictable performance, which translates to fewer unexpected production interruptions. Compatible aftermarket options may provide cost savings but require verification of material quality and dimensional accuracy before purchase. ELGi parts can be sourced directly from authorized ELGi distributors, through industrial supply platforms like Grainger or Motion Industries, or from compressed air specialists who maintain inventories of common wear components.

Material Handling Equipment Considerations

Material handling equipment selection impacts workflow efficiency and workplace safety across all industrial environments. Ergonomic features reduce operator fatigue and related injuries, creating a more productive and sustainable operation over time. Standardization across material handling equipment types simplifies training requirements and improves utilization rates among different operators and shifts. This equipment category can be sourced through specialized material handling distributors, equipment rental services that offer try-before-buy programs, or through used equipment dealers who provide refurbished options with warranty coverage.

Instrumentation and Control Systems

Instrumentation and control systems provide the data and automation capabilities essential for modern manufacturing operations. Compatibility with existing SCADA or DCS platforms prevents integration challenges and reduces commissioning time for new equipment. Calibration requirements and certification standards should align with industry regulations and quality management systems already in place. These sophisticated components are typically available from automation specialists, system integrators who provide complete solutions with ongoing support, or specialized instrumentation suppliers who focus on specific measurement technologies.

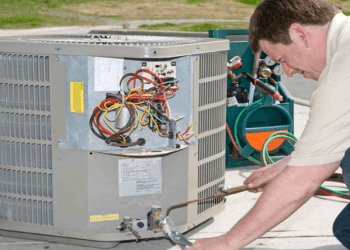

Environmental Control Equipment Selection

Environmental control equipment addresses regulatory compliance needs while often providing opportunities for resource conservation. Heat recovery systems, air filtration units, and water treatment technologies can transform compliance costs into operational savings through resource recapture. Selection factors should include maintenance requirements, consumable components, and the availability of technical support for troubleshooting.

Safety Equipment and Emergency Systems

Safety equipment and emergency systems represent non-negotiable investments that protect both personnel and physical assets throughout the facility. Response time specifications, reliability ratings, and compliance with applicable safety standards should guide selection rather than focusing primarily on cost. Integration with existing alarm systems and emergency response protocols ensures consistent facility-wide safety capabilities. These critical systems can be sourced through safety equipment specialists or regional fire protection companies that provide both equipment and compliance documentation.

Effective industrial equipment sourcing directly influences operational reliability, productivity, and long-term profitability. Plant managers who develop comprehensive procurement strategies create competitive advantages through reduced downtime and optimized performance across all facility systems. Supplier relationships built on technical expertise and support capabilities often prove more valuable than those focused solely on price points. Taking time to evaluate equipment options against facility-specific requirements helps plant managers make informed decisions that support operational goals while managing capital expenditures responsibly.